5 Easy Facts About Plastic Extrusion Profiles Described

Wiki Article

Not known Incorrect Statements About Plastic Extruded Profiles

Table of ContentsHow Custom Plastic Profiles can Save You Time, Stress, and Money.See This Report about Custom Extrusion ManufacturerPlastic Extrusion Profiles Fundamentals ExplainedThe Best Strategy To Use For Custom Extrusion ManufacturerThe Best Strategy To Use For Extruded Plastic Profiles

At Vip, we have years of experience manufacturing countless distinct custom plastic extrusions in almost every shape, size, as well as color you can think of - https://www.brownbook.net/business/51144692/keller-plastics. Our specialized hinges on making plastic profiles particularly for a certain application. You inform us what you require and also we will certainly manufacture it, meeting the greatest high quality criteria.From pre-prototype to post-production, ACE has the capability and modern technology to do it all. We serve huge and also tiny business in markets ranging from vehicle to medical, with tough material demands to limited resistances in America, copyright, Mexico, as well as Europe. No matter where you are or what sector you stand for, you can rely on ACE for individualized solution and consumer contentment.

That means fast quotation service or product suggestion is simply a telephone call away - https://www.goodreads.com/user/show/157924039-john-wynn. Your concerns are constantly responded to promptly by our adept solution personnel, and also you receive the support you require without hold-ups or complication. Thanks for visiting our site, we are here to help you. Please contact your ACE sales rep at 414-332-8133 or email to discuss product or services.

The Best Guide To Plastic Extruded Profiles

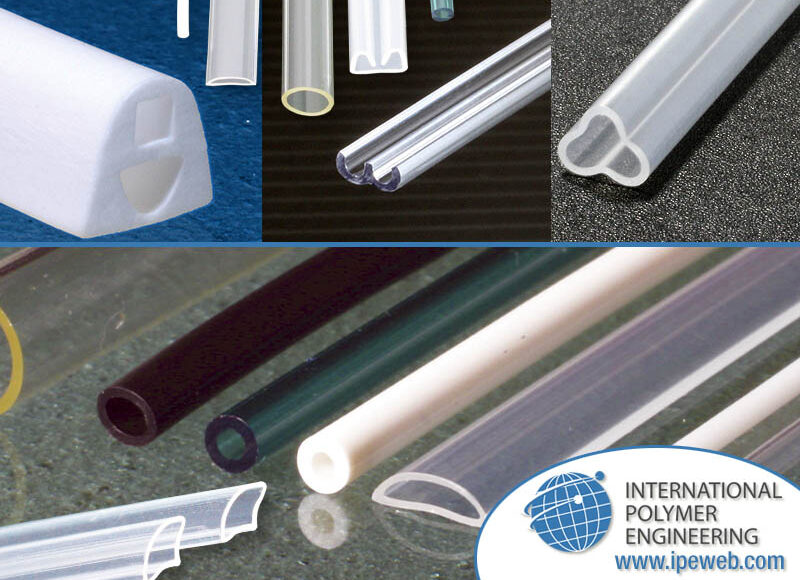

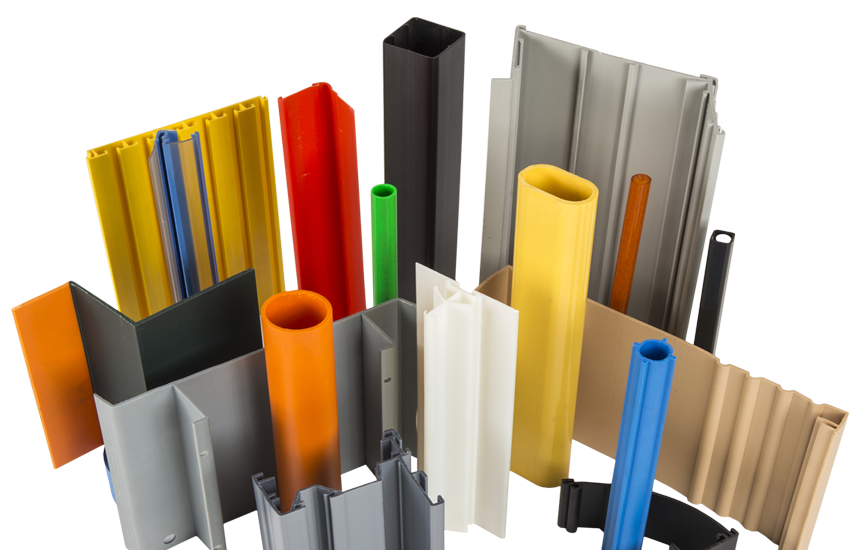

With over 100 consolidated years of experience in plastic extrusion, GSH Industries is a leading B2B distributor of custom-made plastic extrusions, tubing, and plastic profiles in North Ohio. Our designers and designers can help you in selecting the most effective products for your item line - https://www.mitmoradabad.edu.in/elearning/profile/k3ll3rpl4st8/. We have a vast choice of plastic materials and also can match any customized shades to your consumer's specifications - plastic extrusion profiles.It is one of the most popular means plastic components are presently created because of its flexibility. Customized extrusions can be developed into complex forms of differing densities, staminas, sizes, colors, and also textures, and also are reasonably very easy to deal with. The extrusions can likewise be developed with performance enhancing features such as fire resistance, boosted resilience, boosted strength, anti-friction or anti-static residential properties, and a lot more.

It can likewise potentially bring about longer cooling time with will raise your general manufacturing time as well as costs. Sharp edges and notches create powerlessness in the profile where cracking or failure can happen because they lower the impact resistance of the account by producing a high stress focus. If feasible, when developing your account extrusion sharp corners should be stayed clear of all with each other instead goal for rounded corners.

The Only Guide to Custom Plastic Extrusion Manufacturers

015" (0. 381 mm). Ideally the distance ought to be equivalent to the wall thickness of the extrusion too. This adds to smoother product circulation throughout extrusion as well as less anxiety on the account's edges. Hollow accounts and also other details include fairly a little bit of intricacy to an extruded form. They call for added adjustments to the die to make sure appropriate material flow, can cause irregular air conditioning, and also can trigger locations of weakness that can lead to failure.If your component has to have hollows, a hollow within an additional hollow is never a great concept. It will certainly be dislodged of shape before the extrusion strengthens - https://ouo.io/Ya5yss. If your extrusion needs functions such as legs, grooves, snap-ins, or various other things within the extrusion it is best to create a conveniently obtainable opening right into the extrusion to make sure that you can much better integrate those features.

The Facts About Extrusion Of Plastics Uncovered

Understanding some clients may be unfamiliar with our plastic account extrusion abilities, we have assembled a checklist of concerns we are frequently asked. Durometer is a dimension of the product's firmness and is measured with a tool which is pressed versus the account's surface, leading to a dial guage reading.

Typical ranges are Shore A for adaptable products as well as Shore D for stiff compounds. Dual durometer, or co-extrusion, is the blend of 2 or more materials of differing physical homes into a single extruded item. An instance would certainly be an inflexible get rid of adaptable fingers that can be made use of as a gasket or cushion.

Depending on the component complexity and raw materials, one can approximate the expenses starting at much less than $1,000. Due to varying set-up costs as well as run efficiencies, we try to limit the minimum production quantity to 1,000 lineal feet.

The Of Extrusion Of Plastics

What creates the line. If you take a close appearance at an attracting for a plastic account with an intersection leg, you will certainly see there is more mass in the location of the junction. Given that polycarbonate products shrink some throughout the cooling procedure, the junction of two legs cools down at a slower rate than the remainder of the account, causing it to shrink even more due to the mass of the profile.

A tool developer would generally divide the circulation of the 2 legs within the die, as well as enable them ahead back with each other as the extrudate is being compressed to the front of the extrusion pass away. This can in many cases produce a weld line where the 2 melt streams are brought back together so mindful adjusting of the extrusion tooling is vital to lessen this line.

Report this wiki page